PHA Noding: The Goldilocks Approach

HAZOP Nodes

The Goldilocks Approach

We have all heard the fairytale – too big, too small, just right. This same idea can be applied to HAZOP nodes. This blog post will provide a brief introduction into nodes and discuss the pros and cons of different node sizes based off what we have seen.

What is a “node”?

During a HAZOP, the process is broken up into sections called nodes. Nodes are needed to identify and differentiate areas of the process where significant changes in the process operations take place – this allows for the HAZOP methodology to be used most affectively. Nodes can be defined visually by highlighting the desired areas on the P&IDs. Highlighting on the P&IDs indicates to the HAZOP team what equipment and instrumentation are within the node boundary. The HAZOP methodology is then applied to each node.

Who should break up the process into nodes?

It is advantageous for meeting efficiency if the nodes are established before the meetings begin by the HAZOP facilitator. The facilitator fills the required process hazard analysis role, OSHA Standard 1910.119(e)(4), of having one team member knowledgeable in the specific PHA methodology being used. Due to the facilitator being the knowledgeable team member in the HAZOP methodology, they are best equipped to define the nodes before the meetings and prepare the P&IDs accordingly. However, before the review begins, the facilitator should review the scope of the nodes with the team.

How to determine the node scope?

The size of the node could depend on several factors: facilitator’s experience with the HAZOP methodology, facilitator’s understanding of the process, and/or the complexity of the process.

Option 1

Separate the process into small nodes. One way to do this is to define each piece of major equipment (heat exchanger, reactors, tanks, columns, etc.) as a node, and define the connecting piping and associated instrumentation between each piece of major equipment a node. If the piping from one major piece of equipment goes to multiple equipment downstream, define each stream as separate nodes. Figure 1 is an example of noding a P&ID using this method.

Figure 1: Example of separating a process into small nodes

Pros:

The facilitator may feel more comfortable having smaller nodes to ensure all causes for deviations are discussed and nothing is missed.

Cons:

Team could get tunnel vision and not consider how the deviations could affect upstream and/or downstream nodes

Too many nodes decrease meeting efficiency

Creates potential duplicate scenarios that could be difficult to keep consistent

Option 2

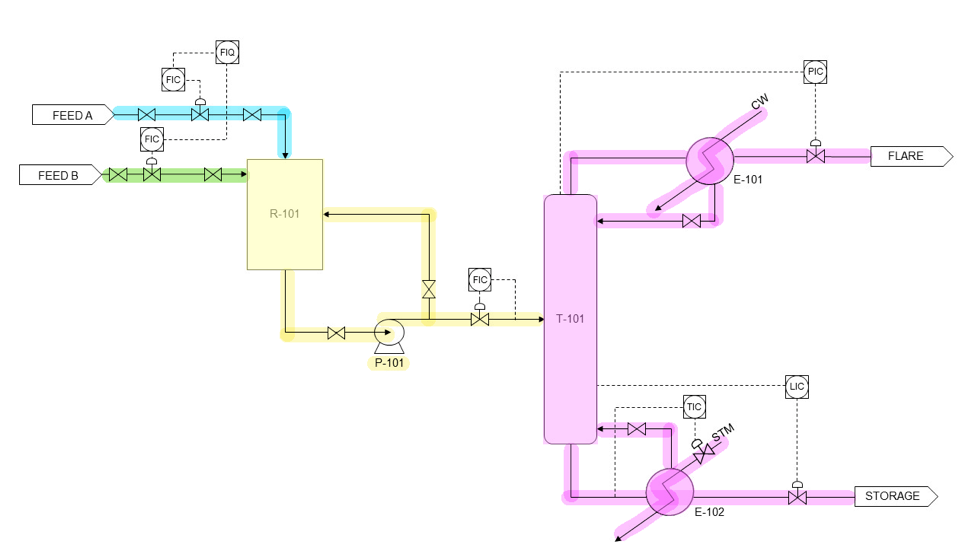

Another option, which is on the complete opposite end of the spectrum compared to Option 1, is to have nodes span multiple, unrelated areas of the process. For example, having a reactor and a distillation column within the same node for a review of deviations is not conducive for the HAZOP structure. Simply put, this is not a noding scheme we would recommend. Figure 2 is an example of a node that is too large.

Figure 2: Example of having one node span multiple unit operations

Cons:

The team will lose sight of the node intention and deviations could be missed as a result.

The team will be unable to focus on one specific operation due to the node having a large span of operating parameters leading to the team jumping around when looking for causes for deviations

Lose the structure that HAZOP methodology provides

Option 3

Creating the nodes based on significant changes in the process allows for the best of both worlds. For example, having a column and its associated equipment as a node, and having a reactor and its associated equipment as another node. This option is what we recommend when separating a process into nodes. Figure 3 is an example of this option.

Figure 3: Example of nodes based on significant changes within the process

Pros:

Ensures the team keeps the big picture in mind regarding how the causes for deviations affect the process.

Meetings are more efficient

Cons:

If the facilitator is not comfortable with the process or methodology this could lead to the team missing causes for deviations.

Final thoughts

The facilitator should keep in mind that the causes stay within the node and look for the associated consequences everywhere else. This is ideal for documentation purposes as deviations will be easy to find when a change is made to the process and the HAZOP must be updated or revalidated as a result. Additionally, the meetings will be more efficient if the causes and consequences can be easily referenced. Although important to the facilitation of the HAZOP, noding is a means to an end. If the facilitator diligently reviews all applicable deviations as they step through the process, the HAZOP will be a success.